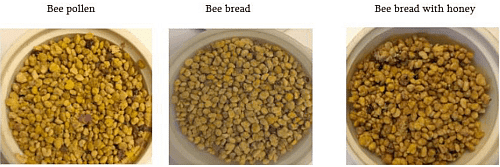

Honey bees bring flower pollen, mix it with their saliva, and place it in the cells. Then, other bees add honey and seal the cells with wax. A bacterial fermentation takes place, followed by a fermentation by yeast. After 15 to 17 days, bee bread is ready.

Bee pollen is flower pollen mixed with bees’ saliva.

The bacterial fermentation

The bacterial fermentation is done with the help of bacteria in the genus Lactobacillus, mostly the species Lactobacillus kunkeei.

These bacteria metabolize the fructose present in the mixture of pollen and honey, and produce lactic acid. The pH is decreased, thus creating a perfect place for a fermentation led by yeast.

The fermentation by yeast

If you are brewing beer, you have certainly heard of Saccharomyces. It’s responsible for the fermentation on many foods, including beer and sourdough bread. It’s the same in bee bread.

Yeast starts to form from bacterial fermentation. While yeast are growing, bacterial fermentation decreases. And yeast come to dominate the bee bread.

The yeasts help to preserve the bee bread and stop pathogenic yeasts or bad yeasts from growing and spoiling the bee bread.

Why do bees make bee bread?

Well, it’s bread, to eat it, of course. 🙂

But not all bees eat it. Only, small children, as we would put it in human terms. From 1 to 3 yo.

In bees terms, after the eggs are hatched, larvae are fed with royal jelly for the first 3 days. After that, the larvae are practically weaned, and the nurse bees bring them bee bread.

Why is bee bread fermented?

picture source Amazon

It is important to be fermented to preserve it for long periods of time. It can be produced in the fall and stored up all winter, to be consumed in lean times.

A colony of honey bees should always stock bee bread. Hard times can come anytime, not only in winter. Summer can sometimes be too rainy, the nectar could be too watery, and pollen can completely lack.

Having stored pollen in the colony is critical to keep producing more workers. That is why the bees preserve this pollen, by fermenting it. Smart girls, I would say.

Bad news for today’s bee bread

Why? Technology, Monsato, greed…. In a word, fungicide.

We already know that fungicides can have a direct impact on bees. But they can also have a indirect impact on the microbiome of bee bread. The diversity of yeast in bee bread is significantly lowered than the diversity of yeast in colonies that have had been exposed to fungicides.

With a decrease of good yeast, we’ll have an increase in pathogenic microbes that could lead to spoilage of the bee bread and potentially even the demise of the colony.

How is bee bread made at home?

The natural fermentation process the bees use can be copied by humans with the help of technological means.

Bee bread can be made with dried or frozen pollen.

Bee bread recipe #1

Here is one old method, as described by KRELL, R (1996) “Value-added products from beekeeping”. FAO Food and Agriculture Organization of the United Nations Roma; 409 pp.

Containers and conditions during the fermentation process:

* The container: Wide-mouthed bottles or jars with airtight lids are absolutely essential. Airtight stainless steel or glazed clay pots can also be used. Containers should always be large enough to leave enough airspace (20 to 25 % of the total volume) above the culture.

* The temperature: The temperature for the first two to three days should be between 28 and 320C; the bees maintain a temperature of approximately 34°C. After the first two or three days the temperature should be lowered to 20°C.

The high initial temperature is important to stop the growth of undesirable bacteria as quickly as possible. At this ideal temperature, all bacteria grow fast, so an excess of gas and acid accumulates. Only lactic acid producing bacteria (lactobacilli) and some yeasts continue to grow. The former will soon dominate the whole culture.

This final growth of lactobacilli should proceed slowly, hence the reduction in temperature after 2-3 days.

* The starter culture: It is best to start the culture with an inoculation of the right bacteria, such as Lactobacillus xylosus or lactobacilli contained in whey. Freeze-dried bacteria are best if they can be purchased, but otherwise, the best cultures are those that can be obtained from dairies.

Whey itself can be used. If the whey is derived from unprocessed fresh milk it should be boiled before use. A culture can also be started with natural bee bread.

* Preservation: Fermentation produces a pleasant degree of acidity (ideally pH 3.6-3.8). Some pollen species may promote excessive yeast growth but this does not spoil the bee bread.

If the flavor is strange or some other mildew-like or unpleasant odors arise from the bee bread, discard it and try again. The final product, can be stored for years, once unsealed, it can be dried and thus is storable for many more months.

General conditions:

For successful fermentation, exact quantities are less important than the correct conditions:

– the pollen to be fermented needs to be maintained under pressure

– the air space above the food needs to be sufficient (20-25 % of total volume)

– the container needs to be airtight

– the temperature should not drop below 18°C

Ingredients (in parts by weight):

10 Pollen;

1.5 Honey;

2.5 Clean water

0.02 Whey or very small quantity of dried lactic acid bacteria.

How it’s done:

Clean and slightly dry the fresh pollen. If dried pollen is used, an extra 0.5 parts of water is added and the final mix is soaked for a couple of hours before placing it in the fermentation vessels. If the mixture is too dry, a little more honey-water solution can be added.

Heat the water, stir in the honey and boil for at least 5 minutes. Do not allow the mix to boil over. Let the mix cool.

When the temperature is approximately 30-32 0C, stir in the whey or starter culture and add the pollen. Press into the fermentation container.

When preparing large quantities in large containers, the pollen mass should be weighted down with a couple of weights (clean stones) on a very clean board.

Close the container well and place in a warm place (30-32 0C).

After 2-3 days, remove to a cool area (preferably at 200C).

8 to 12 days later the fermentation will have passed its peak and the bee bread should be ready. The lower the temperature, the slower the progress of fermentation.

Leave the jars sealed for storage.

Bee bread recipe #2

If you have a little more sophisticated devices like: a biological thermostat, drying oven with enhanced internal

aeration, vacuum chamber and a pressure cylinder with reducer, you can follow another method, explained in detail on biomedres.us.

This developed technology makes it possible to inhibit harmful microorganisms in bee bread: Clostridium botulinum,

Esherichia coli and Staphilococcus aureus even in conditions of deliberate infection of the product. In addition, all its qualitative indicators (pH, oxidation, β-carotene and flavonoids content) remain at the level of standard requirements. Give it a try!

References and further readings: