What happens to manuka honey when it’s heated? At high temperature for more than 10 minutes, all honey changes its composition and manuka honey is no exception.

Regular honey contains sugars, vitamins, hydrogen peroxide, amino acids, proteins, and phytochemicals. Manuka honey is a premium product because in addition to all of the above it contains a characteristic component, methylglyoxal (MGO).

This substance is not something that exists in the flowers’ nectar that bees collect (Leptospermum flowers ) The nectar contains, in varying amounts, dihydroxyacetone (DHA), which is its precursor.

Honeybees transport DHA to a beehive and then store it. Moderate heat (warm conditions) and the period of storage cause the chemical transformation of DHA to MGO in the beehive and also in storage recipients after beekeepers collect the honey.

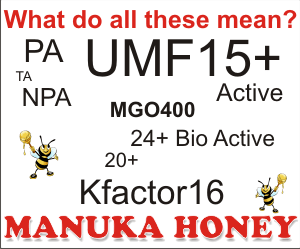

There are 4 chemicals representative of manuka honey, which are used to check its authenticity (along with pollen-derived DNA, like it is done for any other monofloral honey).:

– 3-phenyllactic acid (PLA),

– 2-methoxybenzoic acid (MBA), and

– 2′-methoxyacetophenone (MAP)

– 4-hydroxyphenyllactic acid (4HPA).

Other specific compounds of manuka honey:

– methyl syringate (Beitlich et al., 2014, Kato et al., 2014, Stephens et al., 2010),

– leptosperin (Daniels et al., 2016, Kato et al., 2014, Kato et al., 2012, Lin et al., 2017),

– pteridine (Beitlich, Lubken, Kaiser, Ispiryan, & Speer, 2016), and

– lepteridine (Bong et al., 2018).

Of these, leptosperin has been also used for the grading and certification of manuka honey but the thermal stability of leptosperin is not well validated (Bong et al., 2018, Kato et al., 2014, McDonald et al., 2018).

Manuka honey processing includes:

· Heat. In order to eliminate contaminating pathogens, to extend shelf life, and to increase its fluidity to facilitate filtering and pouring, honey is pasteurized (which means heating!) from 30 min to several hours!

· Time. DHA turns to MGO in time, thus increases its quality and value, and for this manuka honey is kept in recipients for years. But unlike good old wine, the temperature is not controlled.

What happens to manuka honey compounds during heating?

A study published in Food Chemistry on February 2021, conducted by Yoji Kato from the University of Hyogo, Japan, investigated changes in nine characteristic chemicals of manuka honey during heating.

In this study, researchers used manuka honey and milk vetch (Chinese milk vetch, Astragalus sinicus). Manuka honey was classified into 4 grades:

I – non-certified manuka honey;

II – UMF5+ (≥MGO 83 mg/kg);

III – UMF10+ (≥MGO 263 mg/kg);

IV – UMF15+ (≥MGO 514 mg/kg).

The results showed that prolonged heating at 90ºC, for up to 2 hours, decreased the level of MGO gradually, with more than 55%!

This also caused a significant decrease of 2′methoxyacetophenone (MAP).

MAP from heated manuka honey was detected in the gas phase, indicating that MAP was vaporized. The decrease of MAP depended on the volume of headspace in a vessel.

Heating could thus reduce the beneficial and/or signature molecules in honey.

*******************************

So, if you buy manuka honey with a high MGO level and decide to test it for your own, than you should expect a lower MGO content. This happens due to loss or degradation of MGO due to heating at temperatures of 50˚C or more.

So, what is to be done? The truth is that manuka honey is an absolutely amazing natural product with recognized therapeutic properties. It’s expensive and many times adulterated. Commercial honey loses its value due to processing or improper storage and transportation.

Raw manuka honey is the answer that comes quickly in our mind. But not fresh, because if manuka honey isn’t given enough time to turn its DHA into MGO, its antimicrobial power is reduced. Besides, raw manuka honey can be contaminated with the toxin tutin, which is not a thing to play with.

! In the future, at least for medical purposes, they’ll use gamma irradiation to sterilize honey. It’s way better than heating. Let’s hope they’ll do that for table grade honey as well.

! Another valid method would be using high-pressure processing at ambient temperature. The

quality of honey can be enhanced using this method.

A study was done to measure the antioxidant activity of honey.

– applying different pressures(200400 MPa) at ambient temperatures (25 to 33ºC)

– applying different pressures(200400 MPa) at ambient temperatures (25 to 33ºC) combined with moderate temperatures (53 to 74ºC) for 10-30 min;

– applying thermal processing (49 to 70ºC).

The study’s results showed that the best method, the one that can even enhance the quality of honey is by using high-pressure processing at ambient temperature.

Enhance? Yes. The antioxidant activity of high-pressure processing treated samples (600 MPa, 10 min) was found to increase by about 30 %, with no color changes detected.

***************************

Why is honey heated?

Because we use it to produce other products like candies or throat lozenges, toothpaste, and drinks.

We use commercial honey in cooking our meals. There are so many recipes that use honey as seasoning. Heating is used to remove the contaminating microorganisms, to reduce viscosity, and to prevent crystallization and fermentation (Singh & Singh, 2018).

Of course honey is heated when we use it in hot teas, but the temperature is not that high (if we put it when we are ready to drink it, not immediately after we pour the boiling water on the herbs) and we drink it in a short period of time.

********************

References: